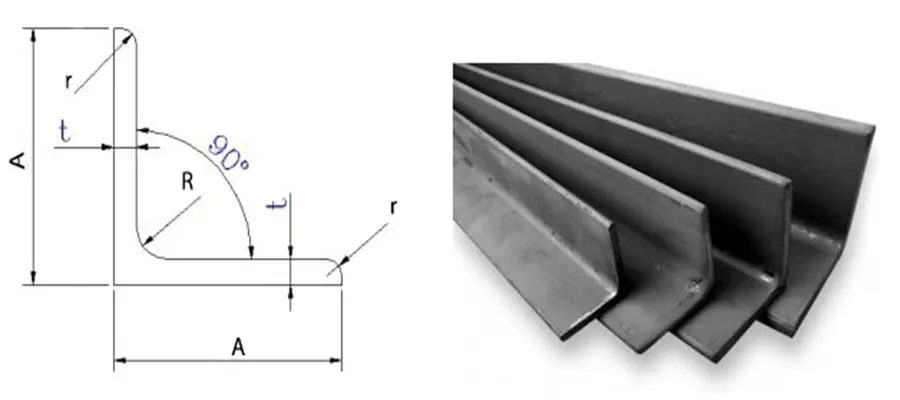

V-SHAPED STEEL, also known as angle steel with a V-shaped cross-section. Steel is divided into 2 main types: normal angle steel and hot-dip galvanized angle steel.

Angle steel is a type of carbon structural steel used for construction. It is a steel section of simple cross-section, mainly used for metal components and workshop frames. In use it requires good weldability, plastic deformation properties and a certain mechanical strength. The raw billet for the production of angles is low carbon billet and the finished angles are delivered hot rolled, normalised or hot rolled.

v Shaped Steel Angle Iron bar

It is mainly divided into two types: equal angles and unequal angles. Among them, unequal angles can be divided into unequal width and unequal thickness. The specification of angle steel is expressed by the dimensions of side length and side thickness. Currently, domestic angles are available in sizes 2-20, with side lengths in centimetres. The same angle usually has 2-7 different side thicknesses. Imported angles are marked with the actual dimensions and thicknesses of the sides and the relevant standards. Typically, large angles with side lengths of 12.5 centimetres or greater are medium angles between 12.5 centimetres and 5 centimetres, and small angles with side lengths of 5 centimetres or less.

- Durability & longevity

- OEM Support

- Eco friendliness

Get steel building design help

Please tell us the overall layout plan and parameter dimensions information of the steel building you want to construct.

Steel Beam - V-SHAPED STEEL

V-SHAPED STEEL

V-SHAPED STEEL, also known as angle steel with a V-shaped cross-section. Steel is divided into 2 main types: normal angle steel and hot-dip galvanized angle steel.V-shaped steel exhibits rigidity, high load-bearing capacity, and exceptional durability. This product is capable of withstanding environmental factors such as temperature, and humidity, and has resistance to chemicals. V-shaped steel sections are primarily used in the construction industry and find applications in shipbuilding and other industrial sectors.

v Shaped Steel Angle Iron bar

Angles, commonly known as angle iron, have two sides that are perpendicular to each other and form an angle. Angles can be

divided into equal and unequal angles.

Angle bars are widely used in: various building structures and engineering structures, such as building beams, bridges, power

transmission towers, lifting and transport machinery, ships, industrial furnaces, reaction towers, container racks, cable

ditch supports, power supply pipelines, bracket installations and warehouse shelves.

steel angle rod structure v-shape

Stainless steel angle can be used to form various stress components according to different structural needs, and can also be used as connectors between components. It is widely used in various building structures and engineering structures, such as house beams, bridges, transmission towers, lifting and transport machinery, ships, industrial furnaces, reaction towers, container racks and warehouse shelves. Stainless steel angle is a kind of carbon structural steel used in construction. It is a simple section of steel used mainly for metal parts and plant frames. Good weldability, plastic deformation properties and some mechanical strength are required for use.

Details

Steel sections are one of the crucial steel materials widely used in the construction industry and various heavy industries. Currently, steel sections are divided into many different types, such as U Beam, I Beam, V Beam, H Beam and C Beam,… . Each type of steel section has a distinct structure and various applications in daily life. The most outstanding advantage of shaped steel is its high durability and extremely good bearing capacity, so for projects that need to withstand high pressure from the environment, shaped steel is the material that needs to be used.

V-shaped steel products are used in building structures, building structures, road and bridge construction, factories, high voltage poles, telecommunications poles, shipbuilding industry, cargo warehouses, foundation piles. factory, factory building structure…

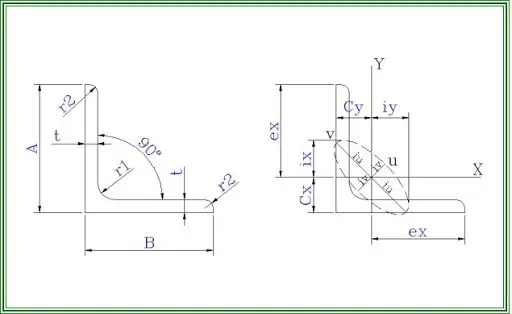

DIMENSIONS AND SECTIONAL PROPERTIES Dimensions not shown in Table shall be by agreement between manufacturer and purchaser. NOTE: The mass per meter length of angled steel is calculated using the following formula: Mass 1 m long (kg/m) = 0,785 x sectional area In which: sectional area: a = (t(2A-t) + 0,215 (r12 - 2r22)] /100 (cm2) r2 = 1/2 r1.

How much do structural building cost?

Prices are affected by different customization needs and may fluctuate considerably. See the article on steel warehouse costs for more details. Get professional advice. Or, you can also directly consult with jinxiuhongcheng’s engineers to get an accurate quote!

Common price factors can be referred to, to facilitate to help you make a preliminary price estimate.

Building size: the larger the scale of your warehouse, the higher the cost of this building.

Degree of customization: the higher the need for customization of your warehouse. Then the building will need to use more materials. Then the corresponding price will be higher.

Building codes: Some areas have specific codes for steel buildings. You may need to pay extra to get the relevant license. But don’t worry, our team is familiar with the building codes of different countries. We can assist you in this task.

Foundation: Foundation construction is also a consideration. Usually we provide concrete foundations.

Transportation as well as Installation: Depending on the requirements of different construction companies. Transportation and installation is also a cost that needs to be considered.Therefore when determining the total cost of the warehouse. Be sure to confirm clearly with the steel structure contractors such as jinxiuhongcheng. To avoid contractual disputes.

FAQ

What are the long-term benefits of investing in a steel industrial building?

Steel industrial buildings are durable. They have low maintenance costs and use less energy. This ensures long-term savings and value.

Can steel buildings be customized for any industrial application?

Yes, steel buildings are highly adaptable to many industrial needs. They allow for customization in size, layout, and specific functions. This lets them suit diverse operational needs.

How do steel buildings contribute to sustainability?

Steel buildings are eco-friendly. They are mostly made from recycled materials. They are 100% recyclable. This reduces the overall ecological footprint.