Galvanized C-beam

C-Channels are standardized channel section. The hot rolled execution has conical flanges, while the laser fused has parallel ones. Both their tolerances are defined by ASTM A 484, the laser fused execution has additionally the product standard defined by ASTM A1069.

C-Channels in stainless steel are used in commerce and industry but also in machinery and equipment building. The use of stainless steel profiles is characterized by a high flexibility of composition and a fast and cost reduced construction (through the possibility of prefabrication in the steel production). Stainless steel profiles are produced mainly from scrap and can be recycled again after utilization so new resources can be conserved.

- Durability & longevity

- OEM Support

- Eco friendliness

Get steel building design help

Please tell us the overall layout plan and parameter dimensions information of the steel building you want to construct.

C Channel in Stainless Steel

Steel Beam - C-Section

If you’re seeking a stainless steel C-Channel profile with non-standard dimensions (up to 1000 mm high), with different thicknesses between flanges and web (up to 80mm) or specific lengths up to a maximum of 15 meters. Our team of experts is ready to help you discover the perfect solution for your project, so don’t hesitate to reach out for a personalized consultation. Explore our comprehensive steel grade list to see all the available possibilities.

Steel Beam - C-Section

C-Channels in stainless steel are used in commerce and industry but also in machinery and equipment building. The use of stainless steel profiles is characterized by a high flexibility of composition and a fast and cost reduced construction (through the possibility of prefabrication in the steel production). Stainless steel profiles are produced mainly from scrap and can be recycled again after utilization so new resources can be conserved.

Steel Beam - C-Section

C-channel steel beams are a type of structural steel beam that is shaped like a "C". They are made from hot-rolled carbon steel and are available in a variety of sizes and thicknesses. C-channel beams are used in a variety of applications, including construction, manufacturing, and transportation. They are known for their strength, durability, and versatility.

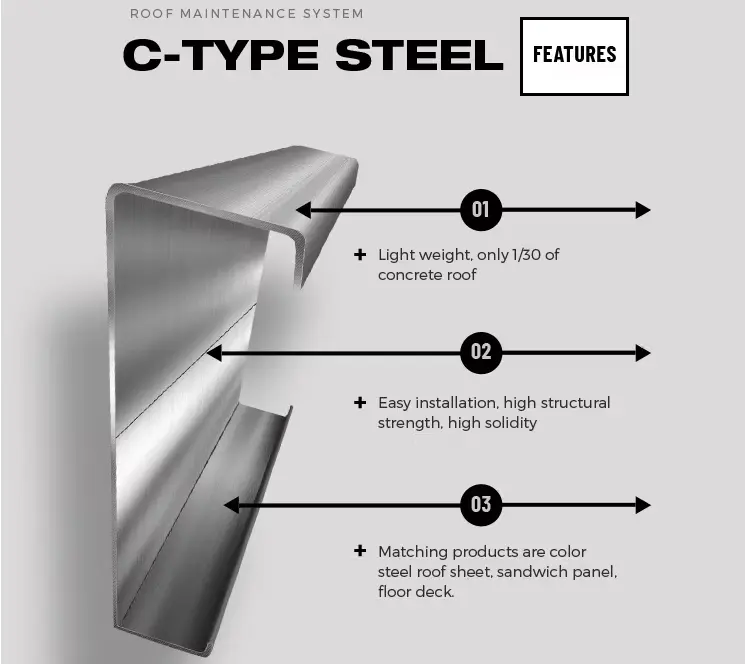

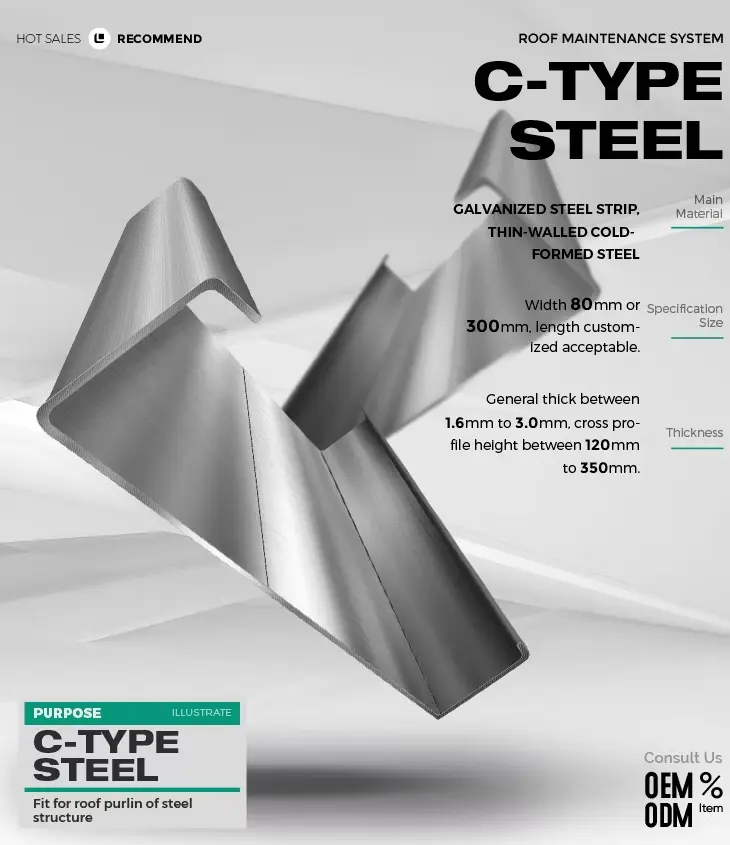

Details

C-Channel Steel Beams are available in a range of sizes with widths between 1.35”-3.15” (3.4-8 cm), depths from 3”-12” (7.6-30.5 cm), and thicknesses between .12”-.4” (3-10 mm). C-Channel Steel Beams are available in typical lengths between 4’-20’ (1.22-6.1 m).

Width: 1.35”-3.15” | 3.4-8 cm

Depth: 3”-12” | 7.6-30.5 cm

Length: 4’-20’ | 1.22-6.1 m Thickness: .12”-.4” | 3-10 mm

C-channel steel is a versatile and reliable material that plays a crucial role in various industries. Its strength, durability, and ease of customization make it a preferred choice for construction, transportation, industrial machinery, and more. By understanding its properties, applications, and maintenance requirements, you can maximize the benefits of C-channel steel in your projects. Whether you’re building a bridge, manufacturing equipment, or constructing a greenhouse, C-channel steel offers the performance and adaptability you need.

DIMENSIONS AND SECTIONAL PROPERTIES

How much do structural building cost?

Prices are affected by different customization needs and may fluctuate considerably. See the article on steel warehouse costs for more details. Get professional advice. Or, you can also directly consult with jinxiuhongcheng’s engineers to get an accurate quote!

Common price factors can be referred to, to facilitate to help you make a preliminary price estimate.

Building size: the larger the scale of your warehouse, the higher the cost of this building.

Degree of customization: the higher the need for customization of your warehouse. Then the building will need to use more materials. Then the corresponding price will be higher.

Building codes: Some areas have specific codes for steel buildings. You may need to pay extra to get the relevant license. But don’t worry, our team is familiar with the building codes of different countries. We can assist you in this task.

Foundation: Foundation construction is also a consideration. Usually we provide concrete foundations.

Transportation as well as Installation: Depending on the requirements of different construction companies. Transportation and installation is also a cost that needs to be considered.Therefore when determining the total cost of the warehouse. Be sure to confirm clearly with the steel structure contractors such as jinxiuhongcheng. To avoid contractual disputes.

FAQ

What are the long-term benefits of investing in a steel industrial building?

Steel industrial buildings are durable. They have low maintenance costs and use less energy. This ensures long-term savings and value.

Can steel buildings be customized for any industrial application?

Yes, steel buildings are highly adaptable to many industrial needs. They allow for customization in size, layout, and specific functions. This lets them suit diverse operational needs.

How do steel buildings contribute to sustainability?

Steel buildings are eco-friendly. They are mostly made from recycled materials. They are 100% recyclable. This reduces the overall ecological footprint.