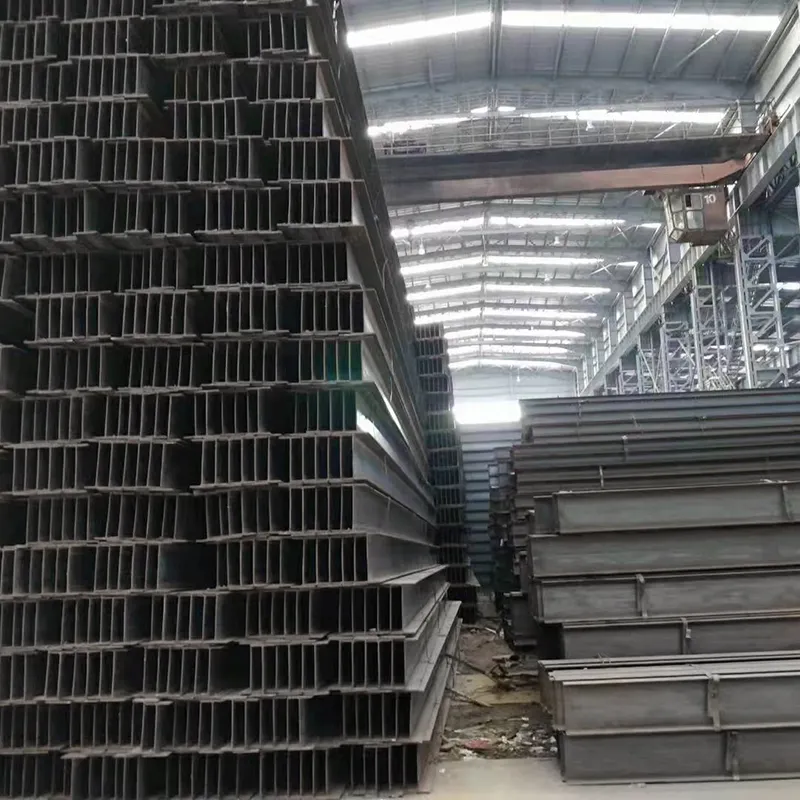

Carbon Steel Welded Steel I Beam For Construction

An I-beam is a standard structural steel shape serving as the essential framework for the construction industry. Structural beams are designed with horizontal flanges and a long vertical section called a web, and the material connecting the web to the flanges is called the fillet.

The flanges at the top and bottom of the beam prevent bending, and the web resists blunt force. These components can withstand a maximum bending load with a minimum amount of material while creating the basis of support for high-bearing loads.

I-beams have depth (the distance from top to bottom), width (the flange length), and thickness, referring to the flange and web thickness dimensions.

The mostly-iron I-beam is considered the universal beam because it can support various loads, making it the most common beam in metal structures.

- Durability & longevity

- OEM Support

- Eco friendliness

Get steel building design help

Please tell us the overall layout plan and parameter dimensions information of the steel building you want to construct.

Steel Beam - I-Section

Steel Beam - I-Section

I-beam is mainly divided into ordinary I-beam, light I-beam and low alloy light I-beam. Ordinary I-beam and light I-beam flanges are thick on the web plate and thin on the outside. Ordinary I-beam, light I-beam, because the cross-sectional dimensions are relatively high, narrow, so the section of the two main sleeve moment of inertia difference is large, which makes it in the scope of application has a great limitation. The use of I-beam shall be selected according to the requirements of the design drawings.

Steel Beam - I-Section

I-beam is mainly divided into ordinary I-beam, light I-beam and low alloy light I-beam. Ordinary I-beam and light I-beam flanges are thick on the web plate and thin on the outside. Ordinary I-beam, light I-beam, because the cross-sectional dimensions are relatively high, narrow, so the section of the two main sleeve moment of inertia difference is large, which makes it in the scope of application has a great limitation. The use of I-beam shall be selected according to the requirements of the design drawings.

Steel Beam - L-Section

Steel beams are strong because of their chemical composition, their manufacturing process, and the shape of the beam. teel is an alloy of iron and carbon, and the amount of carbon in the steel determines its strength. Steel with a higher carbon content is stronger, but it is also more brittle. Steel beams are typically made with a low carbon content, which gives them a good balance of strength and ductility.

Details

H-Section Steel Beams are available in a range of sizes with widths between 4”-16” (10.2–40.6 cm), depths from 4”-16” (10.2–40.6 cm), and shared thicknesses between .35”-.83” (9-21 mm). H-Section Steel Beams are available in typical lengths between 8’-20’ (2.44-6.1 m).

Width: 4”-16” | 10.2–40.6 cm

Depth: 4”-16” | 10.2–40.6 cm

Length: 8’-20’ | 2.44-6.1 m (Typical); 40’ | 12.2 m (Max)

Steel Beams I-beam:

I-beams come in various sizes and lengths, and when these I-beams are galvanized, their life expectancy increases significantly. This is why galvanized steel I-beams are seen as a cost-effective choice for many construction projects.Galvanized I-beams, like regular I-beams, feature a distinct ‘I’ shape, characterized by a vertical ‘web’ and horizontal ‘flanges’. This shape offers an excellent strength-to-weight ratio, making the I-beam suitable for bearing heavy loads over long spans.I-beams, especially galvanized steel I-beams, offer enhanced durability and cost-effectiveness. They form a crucial part of various construction and manufacturing projects, providing structural integrity that stands the test of time.

DIMENSIONS AND SECTIONAL PROPERTIES

How much do structural building cost?

Prices are affected by different customization needs and may fluctuate considerably. See the article on steel warehouse costs for more details. Get professional advice. Or, you can also directly consult with jinxiuhongcheng’s engineers to get an accurate quote!

Common price factors can be referred to, to facilitate to help you make a preliminary price estimate.

Building size: the larger the scale of your warehouse, the higher the cost of this building.

Degree of customization: the higher the need for customization of your warehouse. Then the building will need to use more materials. Then the corresponding price will be higher.

Building codes: Some areas have specific codes for steel buildings. You may need to pay extra to get the relevant license. But don’t worry, our team is familiar with the building codes of different countries. We can assist you in this task.

Foundation: Foundation construction is also a consideration. Usually we provide concrete foundations.

Transportation as well as Installation: Depending on the requirements of different construction companies. Transportation and installation is also a cost that needs to be considered.Therefore when determining the total cost of the warehouse. Be sure to confirm clearly with the steel structure contractors such as jinxiuhongcheng. To avoid contractual disputes.

FAQ

What are the long-term benefits of investing in a steel industrial building?

Steel industrial buildings are durable. They have low maintenance costs and use less energy. This ensures long-term savings and value.

Can steel buildings be customized for any industrial application?

Yes, steel buildings are highly adaptable to many industrial needs. They allow for customization in size, layout, and specific functions. This lets them suit diverse operational needs.

How do steel buildings contribute to sustainability?

Steel buildings are eco-friendly. They are mostly made from recycled materials. They are 100% recyclable. This reduces the overall ecological footprint.