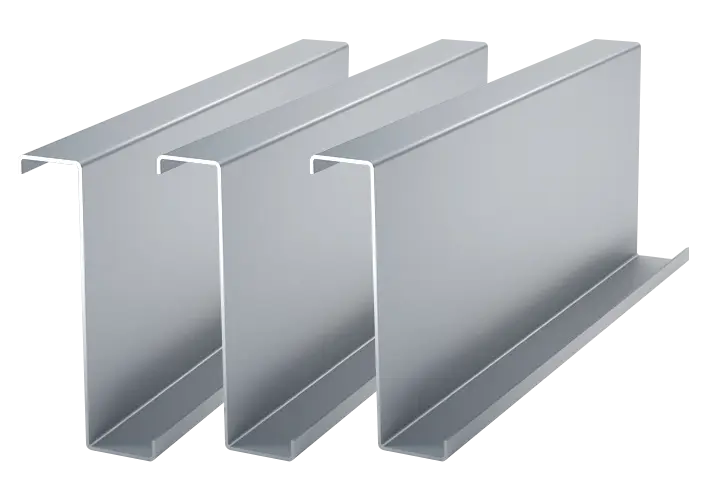

Custom Z-Channel – Galvanized Steel

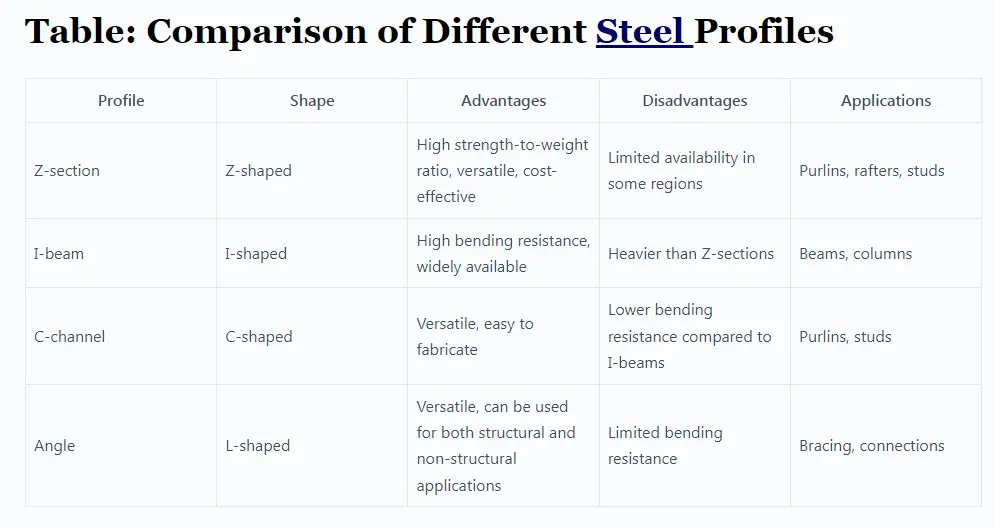

Structural steel Z shapes, also known as Z-sections, are versatile steel profiles that find extensive use in various construction and engineering applications. Characterized by their unique shape, Z-sections offer a combination of strength, flexibility, and cost-effectiveness, making them a popular choice for engineers and builders alike. Structural steel Z shapes are versatile and cost-effective steel profiles that find widespread use in various construction and engineering applications. Their high strength-to-weight ratio, ease of fabrication, and durability make them an excellent choice for a wide range of projects.

- Durability & longevity

- OEM Support

- Eco friendliness

Get steel building design help

Please tell us the overall layout plan and parameter dimensions information of the steel building you want to construct.

Custom Z-Channel - Galvanized Steel

Steel Beam - Z-Section

Galvanized steel sheet refers to a process that covers mild steel with a layer of zinc to provide good corrosion resistance. Stainless Supply offers G90 Galvanized custom Z-Channel, meaning that the zinc coating is a minimum of 0.90 ounces per square foot (total coating, both sides of the sheet). If equally applied to both sides of the G90 Galvanized steel custom Z-Channel, there would be a minimum of 0.45 ounces on each surface.

Steel Beam - Z-Section

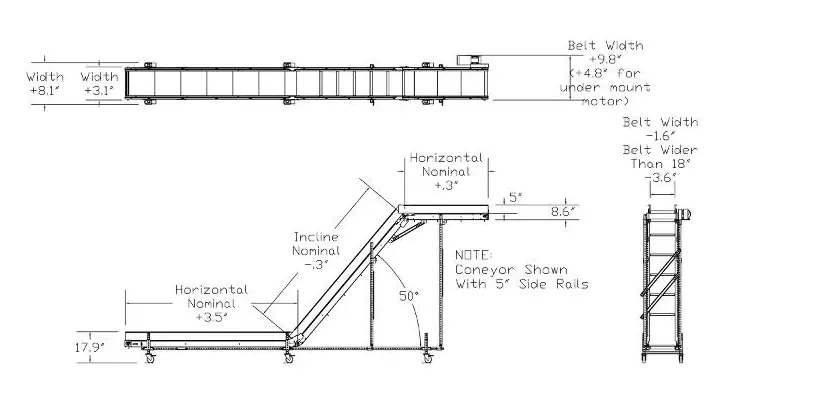

Unlike structural, extruded Z-Channel, our custom Z-Channel will be cut to your specifications and bent in a press break. Therefore, our custom Z-Channel will give customers more variety of fabrication options, including a wide range of bending angles, hemmed edges (on thinner gauge material), flange options, uneven leg sizes, etc.

Steel Beam - Z-Section

Z hot rolled sheet piles have a continuous, symmetrical interlock on both sides of the neutral axis. Both aspects have a positive influence on the sections, as they are located at a considerable distance from the neutral axis. This ensures and increase in strength for a wide variety of applications.

Details

H-Section Steel Beams are available in a range of sizes with widths between 4”-16” (10.2–40.6 cm), depths from 4”-16” (10.2–40.6 cm), and shared thicknesses between .35”-.83” (9-21 mm). H-Section Steel Beams are available in typical lengths between 8’-20’ (2.44-6.1 m).

Z-section steel is a common cold-formed thin-walled section steel, with a thickness of 1.6-3.0mm and a section height of 120-350mm. The processing materials are hot rolled (painted) and galvanized. Its supporting products are: color steel tiles; Rock wool sandwich board; Floor bearing plate, etc. It is mostly used on the roof of buildings.

DIMENSIONS AND SECTIONAL PROPERTIES

How much do structural building cost?

Prices are affected by different customization needs and may fluctuate considerably. See the article on steel warehouse costs for more details. Get professional advice. Or, you can also directly consult with jinxiuhongcheng’s engineers to get an accurate quote!

Common price factors can be referred to, to facilitate to help you make a preliminary price estimate.

Building size: the larger the scale of your warehouse, the higher the cost of this building.

Degree of customization: the higher the need for customization of your warehouse. Then the building will need to use more materials. Then the corresponding price will be higher.

Building codes: Some areas have specific codes for steel buildings. You may need to pay extra to get the relevant license. But don’t worry, our team is familiar with the building codes of different countries. We can assist you in this task.

Foundation: Foundation construction is also a consideration. Usually we provide concrete foundations.

Transportation as well as Installation: Depending on the requirements of different construction companies. Transportation and installation is also a cost that needs to be considered.Therefore when determining the total cost of the warehouse. Be sure to confirm clearly with the steel structure contractors such as jinxiuhongcheng. To avoid contractual disputes.

FAQ

What are the long-term benefits of investing in a steel industrial building?

Steel industrial buildings are durable. They have low maintenance costs and use less energy. This ensures long-term savings and value.

Can steel buildings be customized for any industrial application?

Yes, steel buildings are highly adaptable to many industrial needs. They allow for customization in size, layout, and specific functions. This lets them suit diverse operational needs.

How do steel buildings contribute to sustainability?

Steel buildings are eco-friendly. They are mostly made from recycled materials. They are 100% recyclable. This reduces the overall ecological footprint.